Green-Built Hudson Valley Houses - What Is Hempcrete?

Posted by Coldwell Banker Village Green Realty on Friday, March 31st, 2023 at 9:20am

Last week, two of our agents and one of the members of our marketing team sat down with the designer and builder of the Hempcrete houses that are newly available in Stone Ridge, Paul Petrov. Paul is first of all, a ton of fun, second an expert in green building technologies who’s willing to share his deep knowledge and total enthusiasm for the topic, and third a lover of the Hudson Valley landscape and lifestyle. What follows is an edited – by half – version of our talk. Frankly, we could have talked and learned from Paul for twice as long as we did. We’re sharing the portions in which we didn’t veer wildly off-topic – we kept it to building and architecture! Here are all our (and your) questions about building with Hempcrete answered!

CBVGR: Paul! It's so nice to have us all here in one room instead of communicating via email forward! Let's dive right in because there's so much we want to know about this project. We read on your website, that you have a pandemic story. Let’s hear about how you ended up here doing this in the first place.

Paul: Well, we had place in Saugerties and we were coming up here quite a bit. We actually bought a little land and we rented a house right next to it. We were going to build some shipping container houses there (or something like that) just for our amusement while we were here on weekends. And we wound up buying the house that we were renting to use as a field office just before the whole pandemic thing really hit high gear and it became really important to have that house. So that house became our main thing. At the same time, we were already starting to do work up here in addition to in the city - we were picking up land because we wanted to do projects up here. And then there was the covid pause and all the construction in the city was shut down. We were putting up a condo building on the Upper East Side, and for a while it looked like the construction wasn't going to stop, and then it did stop for a number of months. So we just stayed up here in Saugerties and worked on our house, which is much nicer than it was when we bought it, and we started working more intensely on our projects up here. That’s when things became a little more serious for the Hempcrete houses in Stone Ridge and we started to get polished designs together, study the building envelopes and learn what to build them with *laughs* so that we could make them healthy and efficient.

CBVGR: We know you're using a lot of really innovative materials! But, before we go there, let’s backtrack because you said three of my favorite words in combination, "shipping container house." Did you end up building those?

Paul: We did! I have one sitting out in my backyard. We built one last winter, not one to live in, so we weren't trying to go for the super-efficient little box with a thousand drawers to put things in and with stuff coming down from the ceiling. It's a simple, naturally built, nicely finished box with enough doors and windows, and a beautiful little Japanese porch on it. It's insulated with hemp wool and finished with hemp oil, and there's no styrofoam in it, and it's non-toxic (except for the plastic in the windows, which are hard to avoid). It's great! It's easily heated. We have it plugged into an outlet and it does everything we need it to do. We did another one as our field house, which is at the properties in Stone Ridge now. We use it to display drawings and material samples and everything, all the stuff related to the projects there.

Paul: I like shipping containers. They're great. They're also restrictive because they're narrow. When you're working with them, it's not necessarily cheap, sometimes people think they're a cheaper way to build. It's really not - in some ways it's more expensive because you have to do things to make the rooms wider than seven feet (laughs) - you have to have a plan. I've got some good designs on the shelf for shipping container stuff, and I'll probably do it. You know, what we used to do? We took shirt cardboard and we would make little scale models of the shipping containers, 20 footers and 40 footers, and then just take them and throw them down on the table, like jack straws, and see how they randomly came together, and photograph them. So, I have all these pictures of randomly assembled shipping container models, and some of them are pretty cool. So, we may just do something like that, a totally random assembly of shipping containers.

CBVGR: Oh, that's so neat! I can totally imagine what that would look like, but I'd never be able to imagine how to actually make it happen! Which brings us back to the topic at hand because it’s a little hard to imagine hemp as a construction material. What first made you interested or attracted to Hempcrete as a building material?

Photo Credit: HempWiki.com

Photo Credit: HempWiki.com

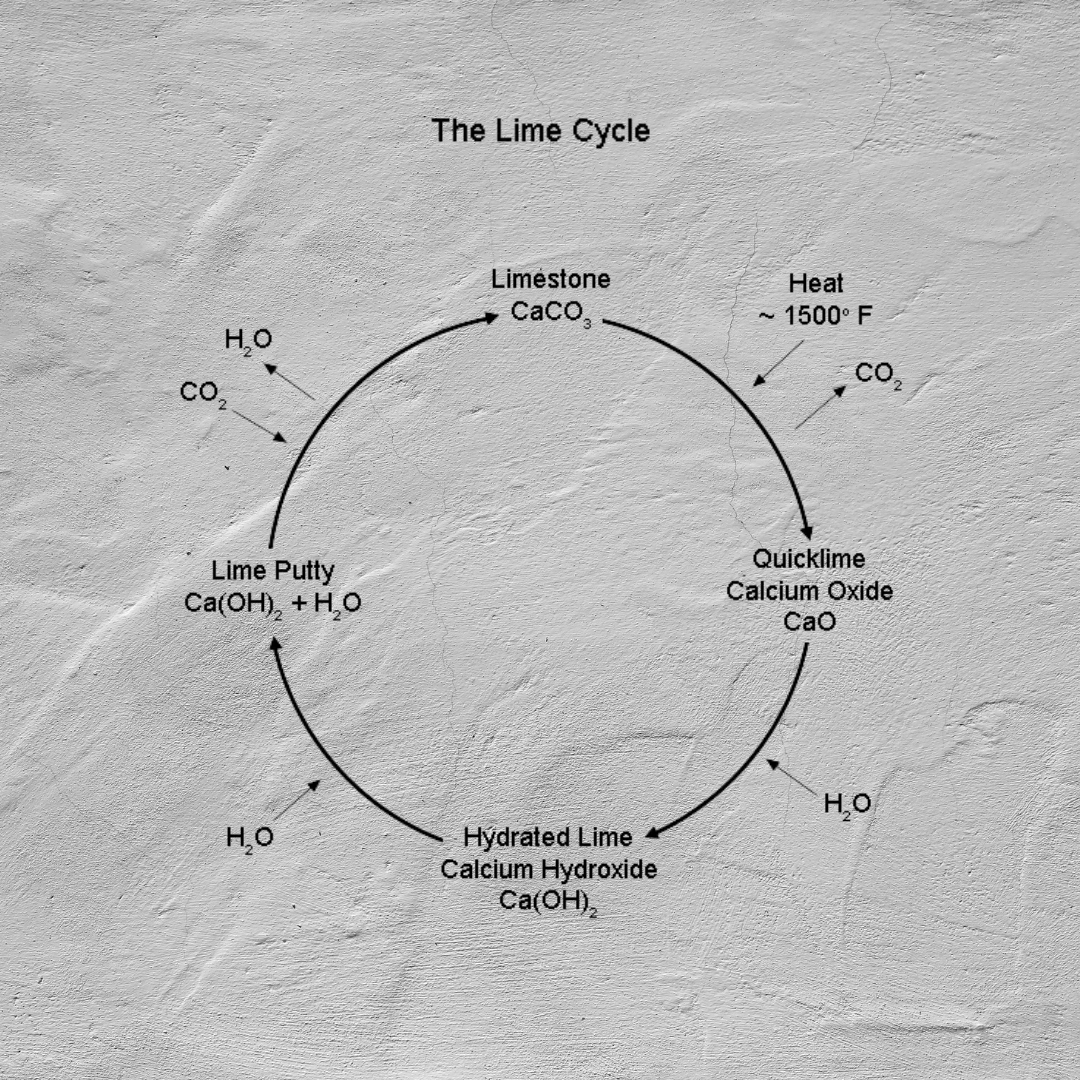

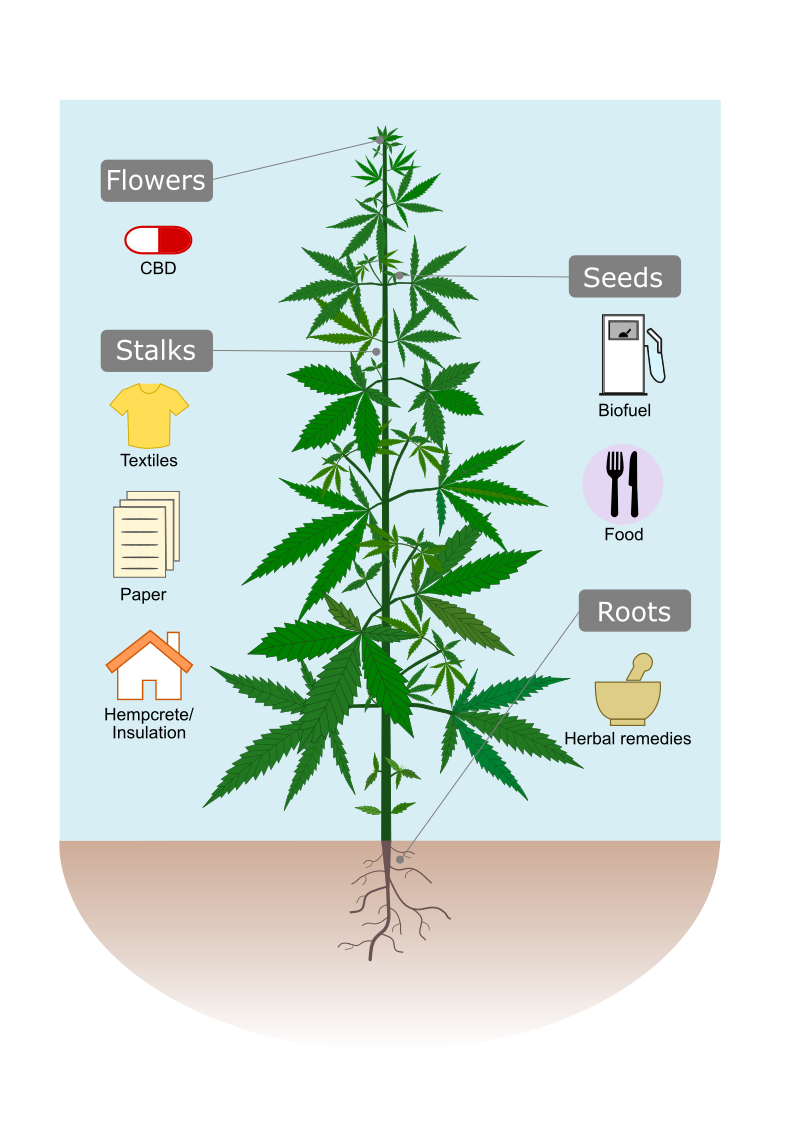

Paul: Now, with Hempcrete, everybody’s tendency is to focus on the hemp, but the lime is really what it's about - the lime binder that holds the hemp aggregate together. Concrete is made from Portland cement, gravel, and sand; Hempcrete is made from the hurd of the hemp plant and lime mortar instead of Portland cement, and lime is a material that's been in use for thousands of years. I have a lot of experience with lime mortar and lime plasters. I've done a lot of restoration and historical renovation in New York City, in addition to all the commercial work that I've done on Park Avenue and so forth. So over the years, I've had really good plaster mechanics that use lime putty that comes from Europe and know how to work with it.

CBVGR: Ah lime! Now I feel like this material is just as much a throw-back as an innovation. Wasn't lime used in the Sistene Chapel frescoes?

Paul: Yes, and I like it, and it’s been used so long and lasts so long because lime breathes - it absorbs and releases water. In part I use it because I'm just really comfortable with that material, I believe in it, I've done a lot of stuff with it, I understand what it does - it's not a novelty to me. In trying to get a really good building envelope for residential construction with really high energy performance, I was drawn to the Hempcrete block rather than the passive house assemblies that are popular now because of its simplicity - it's a single material. It's hemp and lime. It's not the layers upon layers of material that you'll find in a passive energy home – that’s stick framing, and another course of stick framing with insulation in between, and an airtight membrane on the outside on the sheathing, and a vapor permeable membrane on the inside, and then drywall, and then some latex paint that doesn't really breathe, and a rain screen siding on the outside. With that kind of construction you end up with 10 or 20 different materials. I was drawn to the simplicity of the Hempcrete envelope and its great performance which goes so far beyond things like the R value of the house. Hempcrete material does a lot - it's not just a warm balloon *laughs*, it breathes, it regulates humidity, it sinks carbon - the more you learn about it, the more compelling it is.

CBVGR: So, let’s get into the nitty-gritty. Is it structural? Is it actually on the interior and exterior of the homes?

Paul: The Hempcrete is not structural, it is envelope material, it’s an insulator and a finish. Then there’s an integral concrete super-structure that supports the roof loads and supports the building. The interior and exterior are "lime render" or clay plaster. Lime render is a plaster - it's made from naturally hydraulic lime from Europe mixed with different sands and silicates. On the exterior it's about an inch thick, on the interior it's about a quarter of an inch thick. One of the nice things about it is that it's really not limited in terms of color or texture. You can do a lot with it, from rustic finishes that have a lot of sand and a lot of tooth in them all the way up to the most polished and sophisticated venetian plasters. The Hempcrete walls perform very well and feel great when you put your hand on them; sometimes we finish the plasters with linseed oil or with olive oil - there are great olive oil finishes that go on the plaster and feel very silky. The finishes are a wonderful aspect of the work. It's different than just taping drywall and slapping some latex plastic paint on the wall.

CBVGR: It sounds like it has to be all hand-applied!!

Paul: It is hand applied. We do use something called the PFT Ritmo pump on the exterior to put the plaster on. When you're doing a full plaster application like stucco on the outside of the building or a skim coat on the inside of the building, getting the plaster onto the wall is where a lot of the labor is; it's moving a lot of material, right? So when we're plastering the outside of a building like that, we use a pump just to get the stuff on the wall, and then they trowel and steel it by hand to make it flat and smooth. That's done in a couple of applications, usually three on the outside and on the inside, usually two applications.

CBVGR: So tell us a little bit more about the Hempcrete itself. It’s not commonly used in the northeast. Where's it manufactured? Does it come in just one kind of block or can you get lots of different blocks in different shapes and sizes? Do you have to cut them once you get them? Are they like legos?

Paul: *laughs* The blocks come in different thicknesses from seven and a half centimeters up to 36 centimeters by 60. The ones we're using are 30 centimeters. They're about a foot tall and two feet wide, and about a foot thick. Some are drilled through to allow core filling to make columns. They also have u-shaped blocks which are used for bond courses. It's really very similar to concrete block in terms of how it goes together and how it's reinforced. Over window openings we use bond blocks with rebar cages in them and concrete is placed to form the structure. To cut them you can use a hand saw or a band saw, and we also use saws that are typically used for terracotta block in Europe where you have two blades, one that goes forward while the other goes backward, so you don't have to hold the block, the blade just cuts through. If you've ever traveled in Europe and seen the construction over there where they have these slender reinforced concrete super structures and they infill with unit masonry like terracotta block or concrete block and plaster it over, it's really quite similar to that. It's exotic in that it's Hempcrete, but that's the only thing that's exotic about the construction; everything else people have been doing for ages in Europe. I had to hire a European structural engineer because he understood the construction. That sort of building is uncommon here. Everything's two-by-fours because historically there was a lot of wood available in America, but what we're doing is completely natural and normal to anybody who's not American.*laughs*

CBVGR: *laughs* To your point, we shared one of the houses on social media the other day and someone said, "Oh great, a house made of weed.” *laughs* Do you get that a lot?

Photo Credit: authorea.com

Photo Credit: authorea.com

Paul: Sometimes, there are a lot of marijuana enthusiasts out there, and that's alright with me, but it's not why I'm using it. I'm using it because it's very difficult to find natural building materials. You know, the petrochemical industry is just so entrenched in everything we do. You can reach out and touch something plastic right now, and you're probably wearing something plastic, and I'm probably wearing something plastic, and that's not good. We have two real estate brokers on this call. You guys have any houses that don't have styrofoam and plastic in them? It's pretty hard to find a house that's built with natural material. And that's why I use the Hempcrete block. They use other bio fibers to make blocks like these too. This could be done with sunflower stalks. There's a company in California that's using recycled bio-fiber from corn stalks. They have a method by which they sterilize that material and then make blocks using a lime binder. I don't think they're online with it yet, it's in development. It's hard to get the stuff! I have to ship everything from Europe right now, but it's changing - it's going take time, more time than it should take because you don't have oil companies financing it, so entrepreneurs have to do it themselves. It takes effort.

CBVGR: Indeed. We’re curious about the foundations for the Hempcrete houses. Is there anything different about the foundational structure for a house that's built of Hempcrete?

Paul:The structural requirements don't change. You have to hold up the building and it's a reinforced concrete building. We are using frost-protected shallow concrete foundations. What is different about our foundations is that they're not insulated with Styrofoam. I read that styrofoam is an endocrine disruptor and I never liked it anyway – I don’t want to use it. So instead of Styrofoam, we're using recycled glass foam-board and glass foam aggregate as insulation for our foundations. It's expensive and unusual but we're doing it because we don't want toxic foundation insulation around our house.

CBVGR: And you use the glass down there instead of wool or another green insulator because it doesn't take on moisture?

Paul: We use the glass foam-board because of its high insulating value, it's fire resistance, it's compressive strength - it's actually strong enough to hold up the house without concrete - it's pretty good material. I spent a lot of time trying to figure out how to insulate a foundation without Styrofoam. It's not that easy to come up with a material that'll work that way. I want to develop some foundation systems that are healthy and a little less expensive than what we're using so they're more accessible.

CBVGR: We think there’s a possibility that some people might be concerned that because hemp is biodegradable their hempcrete house might biodegrade. It's a somewhat illogical thought because wood is biodegradable and the majority of the older homes in our area are were built with wood, but never-the-less, the thought occurred to us, so it might occur to others…

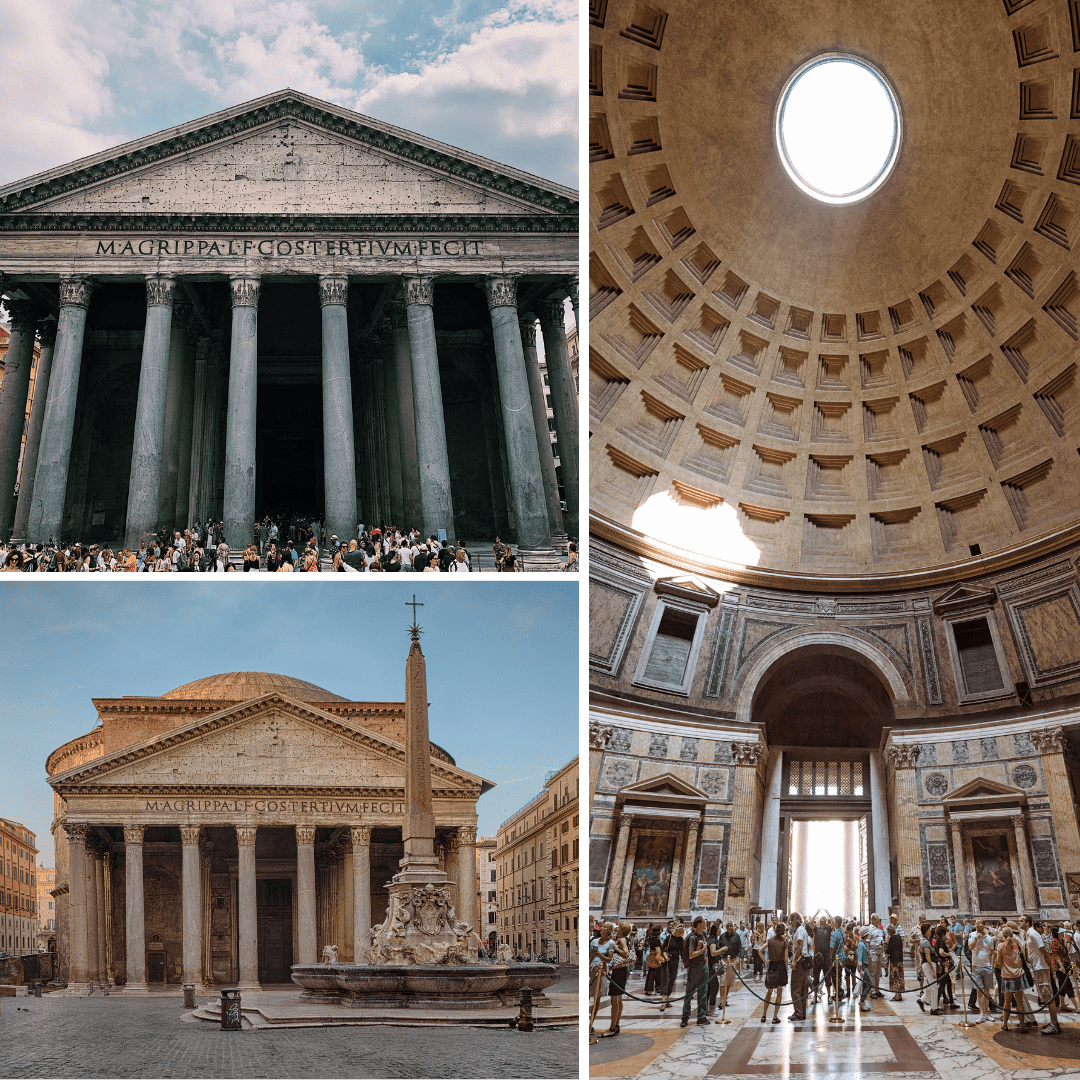

Photos of the Pantheon, Built In Rome Using Lime & Volcanic Ash Mortar in 125AD

Paul: Really the lime is the star of the show. You know, lime mortar can be thought of like cement, is what's holding up so many historic buildings in Europe; and a lot of the buildings here, too. We've worked on rowhouses that were built with lime mortar that are 300 years old in Brooklyn. The Hempcrete houses will stand for hundreds of years. They're building this way in Scandinavia and in Canada. Hempcrete is actually very popular in Canada. They're doing a lot of cast-in-place construction up there. Most of the Hemcrete construction on this continent is cast-in-place, where they build form work, and they pack the hempcrete material into the forms by hand, on site. It takes too long to dry in my opinion. There are some mineral additives that have been developed that help with that, but we're using the blocks to avoid that drying time. My mentality and orientation is based in my history in commercial construction where efficiency is really important. It's not really towards having a good time with my friends, playing with Hempcrete.

CBVGR: Making a giant mud pie....

Paul: *laughs*

CBVGR: So let's talk about the land in Stone Ridge. What attracted you to the setting and the parcels?

Paul: Yeah, it's a really nice experience going up to the Stone Ridge properties, the long gravel driveway I really liked, you know, it sounds stupid for a guy building natural houses to talk about how much he likes driving around, but it is a pretty nice experience coming up there. And just the way the land is set up and the way the road is beautifully built-in. And then you have these nice parcels of land with a rolling landscape and good privacy there. Each one is its own thing. It's mountainous land, which I like. It has mountaintop vegetation, sturdy oak trees - it's not a densely wooded jungle (laughs). There's really good air flow through there as a result. On a hot summer day, you don't feel it - the humidity's not as bad there as it might be in other parts of our area.

CBVGR: Now for the fun part...the design. You've said the designs are inspired by California ranch style and Japanese and Scandinavian influences. Why don't you talk a little bit about how you conceived of the designs and how you feel about them.

Paul: It's all just the design I like, really. It's not much more complicated than that. When I was a kid, we lived in some pretty nice old buildings, moved around a good deal. One of the houses we lived in in Woodstock was a giant renovated barn on Zena Road. Fantastic building, fantastic place. And when I was young, I worked for a company called Barn Homes, which was an early builder of the post-and-beam barn-style homes that became a trend in the seventies and eighties when people started repurposing old barns for homes. Then, the resulting new construction in that style became kind of sterile. They started doing CNC fabrication and the post-and-beam houses they were building didn't have the same character.

Paul: Then I became aware of the Japanese Gassho style, which is 16th century peasant architecture, wherein itinerant framing crews would put up the frame from the sill to the top plate, a lot of times using trees that grew out of the side of a mountain. When a tree grows out of the side of a mountain, it starts out perpendicular to the land - so it comes out at an angle, then it turns up vertically to go up and get the sun. The Japanese would use the whole tree, including that haunched aspect, and the result would be some strikingly beautiful frames. Then the peasants would put the roof on top using poles and thatch. They had steep roof pitches, and the houses were quite beautiful and had real character. All the finishes were made from naturally occurring materials - not a lot of high tech fabrication in the 16th century. Coincidentally, it was very similar to what was happening in the Scandinavian part of the world. The mountainous landscapes were similar and the way people lived was similar; the resulting architecture and design was all quite similar. I think they even have a word for the combination of the styles... Japandinavian?

So, I like that stuff. Our first iteration of these houses, at a project we've done in Gallatin, was a two-story cabin in that style. It’s a great building. It's what we're offering on our lot 3 in Stone Ridge - 25 Clendening is the same design. But, then in Gallatin, we had a kind of a slightly smaller parcel with a really nice hill, and we didn't want to overpower the hill with tall house - I didn't want to take away from the hill. Some people would build on top of the hill, but Frank Lloyd Wright would say, when you do that, you lose the hill - so you don't build on top of the hill most of the time. In that case, we're building a garage into the hill, so it's just a little eyebrow with a green roof on it that you barely notice, and then we're building a single story ranch house. I learned about ranch houses when we bought one accidentally here in Saugerties (he jests). And I started studying the ranch house. Before that, I was never that interested in them. But, it's fascinating, the whole story of the post-war housing boom in California and the cast of characters that were building and developing those tract houses out there. Some of the early pre-war ranch houses were just simple bunk houses - long and straight - and that turned into this mid-century modern meets ranch house style. Some of it's very cool. I came to really like it and be fascinated by it. I really like them and I look at houses differently now.

CBVGR: What made you add the solariums to the houses? We love the solariums.

Paul: The project in Gallatin has a breezeway that connects the garage to the house. And the structural engineer wanted to put some big steel in there because it's a long span. So here he is with his two foot tall I-beams going across, three of them, overpowering everything. You can't look at it, it holds the roof up, but it's no good, you know? So how do you make that smaller? You make it smaller by putting some legs in, and so you put some legs in, and now you have the beginnings of a wall. So what do you do with that? You put some glass in and now it's a greenhouse, and now you take the whole roof out and just build a greenhouse next to the house. *laughs* I'm not inventing the greenhouse attached to the house! It's being done again and again in Europe and Sweden. I think there are some good examples out there. There's an architect, Bruno Jacobsen, who did a great house, a Nordic barn-type house with a greenhouse between two barns. It's just fantastic. That guy's doing some great things. We started drawing the solarium, and then we did the renderings, and then I gave it to some greenhouse guys and we've made it up-to-spec for interior living space - it has the right kind of glass, you can heat it and cool it.

CBVGR: They're really pretty. We also love that you have an option for an organic garden with raised beds that's ready to go. Tell us about the other add-ons you're offering in Stone Ridge and how you feel like they'll be used on the properties.

Paul: They're really just things that I want myself or have myself, that I think everybody should have, right? Everybody should have a pool and a garden living here. Who wants to go to the supermarket and get pesticide sprayed vegetables and then wash the pesticides off with baking soda or some other stuff that you buy, it's better to just go and pick it out of your garden. I love walking out to my garden and grabbing a couple cucumbers and tomatoes and making a nice chopped salad with a little feta cheese and red onion, and knowing that nothing bad ever touched my food. You have to have that. Now I'm learning about pickleball. We have a buyer, great people, and they want a pickleball court.

CBVGR: Apparently it’s the fastest growing sport in America!

Paul: I didn't even know there was such a thing! My retirement plan was to gamble on shuffleboard - I was going to start practicing before I turned 65, so I'd have an advantage. . Now it seems to be pickleball is going to be the thing - you know, I might have to work a little harder and I'll need a pickleball bracelet.

CBVGR: *laughs* We can learn together. So! If you were going to build yourself one of these homes, which design would you choose?

Paul: All of the designs are based on my feelings and my needs and, and what I think everybody else needs and should have without being too grand. But, the one that I think I like for me is the Hana Toshika, which means, the flower and deer. It has a really good size hallway, which is kind of like a library - it's big and can support a lot of furniture and art going into the master bedroom. It also has a big home office with a separate entrance lobby, and otherwise a very good flow. I pay a lot of attention to flow and traffic. You know, I've worked on a lot of restaurants and my head is into that kind of design, into the flow. Where does everybody go? Can you walk over there without bumping into something or someone? Can two people walk past each other here, and why are they walking past each other, and where are they going? And then what are they going to do? And does everything really work? You know, it's like chess. I used to be a really good chess player. Now I don't have the attention span for it - I'm thinking about too many other things, like traffic and flow.

CBVGR:Paul, we learned so much! We didn’t get any pickleball tips, but maybe next time. Readers – if you have any questions about Hempcrete that we didn’t ask Paul, comment below and we’ll get you answers.

Leave A Comment